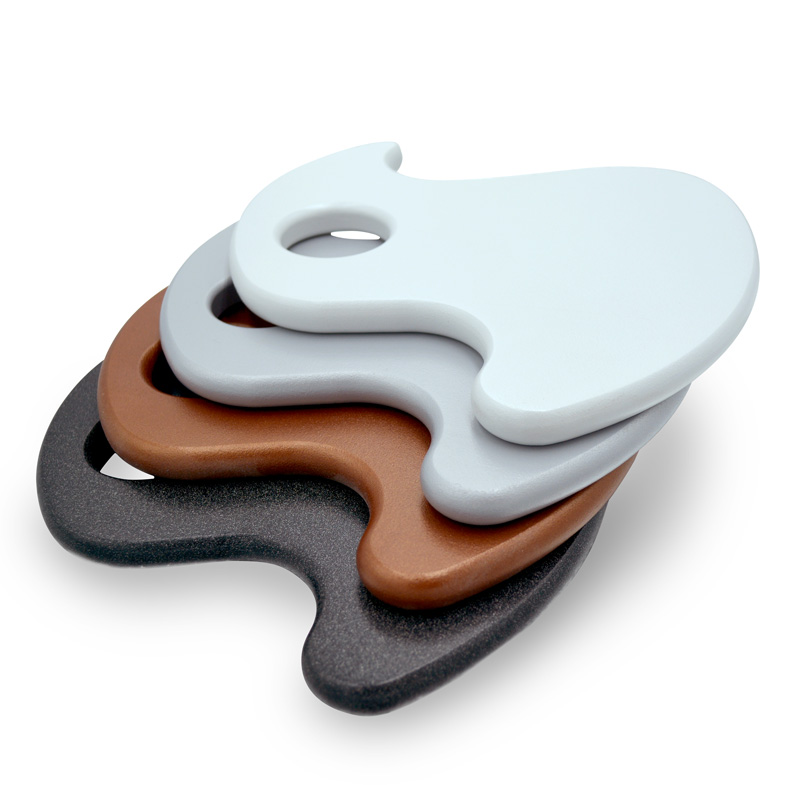

UVMax® UV Cured Powder Coatings

Innovative finishes that combine both functionality and performance for MDF, birch and other wood based substrates.

Available in wide range of colors, glosses, and textures, a coating can be custom formulated to meet your specific finish or performance requirements.

UVMax® is our original line of opaque semi smooth finishes for MDF. We have a select color range of stock finishes and our sister company Keyland Polymer UV Powder has the ability to custom color match to any Pantone, RAL, laminate, paint, or supplied sample.

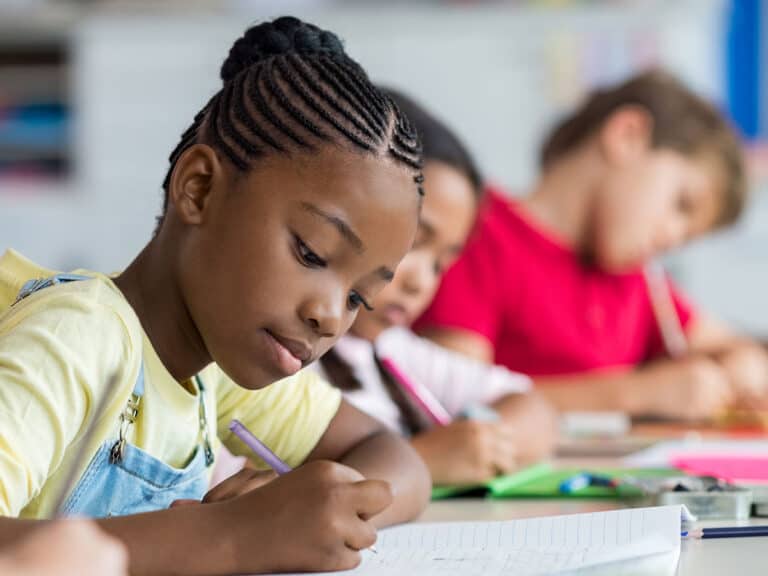

Suggested Uses: cabinet doors, kiosks, work surfaces, shelving, wall panels, end caps, media carts, desks, store fixture and display components, office and educational furniture, healthcare components and other architectural elements.

Design Freedom

Maximize your design possibilities for your next project.

- Bullnose, radiused and waterfall edges, built up components, cutouts and contours.

- A seamless finish that flows smoothly over complex shapes.

- No edgebanding- 360° coverage for any component, three-dimensional or not.

Sustainable Process & Materials

A finish that won’t harm the environment.

- VOC and PVC FREE, no solvents or HAP (hazardous air pollutants)

- SFI (Sustainable Forest Initiative) certified MDF and CARB (California Air Resources Board) phase I and II compliant

- 100% recycled wood content

When Durability Matters

UV curing is instantaneous, resulting in a highly durable finish with superior wear characteristics.

- Strong cross-linked photopolymer bonded finish

- Stain and scratch resistant with an easy to clean surface

- No cracking at 35″ (NEMA ball drop test)

Efficient Finishing Process

We make custom components based on your specifications. A fast, cost-effective and worry free process.

- You send us the drawings, we CNC machine, powder coat and ship you finished parts.

- Single step one coat process, just 20 minutes.

- No primer, topcoat, or waiting for paint to dry between layers.

Antimicrobial

UVMax® Defender using Bactiblock technology is available for all resin chemistries in our UVMax® powder coating line without hindering coating appearance or performance. The antimicrobial agent uses silver ion technology that attaches to the cell walls of a microbe, interrupting enzyme production and DNA replication.

Applications

- Hospitals

- Schools

- Gyms

- Child Care Centers

- Public Transportation

- Restaurants

- Laboratories

- Medical Facilities

- Airports

- Hospitals

- Schools

- Gyms

- Child Care Centers

- Public Transportation

- Restaurants

- Laboratories

- Medical Facilities

- Airports

Antimicrobial Efficacy After 24 Hours

Independent third party testing was performed in accordance to ISO 22196 standards. After 24 hours, surfaces coated with UVMax® Defender showed both E coli and Staphylococcus bacterial reproduction reduced by more than 99.99%.